Best Practices for Crane Load Management

Effective crane load management is important in the interest of safety, wear and tear on equipment, and delays to your project that come with heavy costs. Adherence to recognized industry crane load practices can increase efficiency and compliance in any environment that utilizes tower cranes, mobile cranes, or derrick cranes.

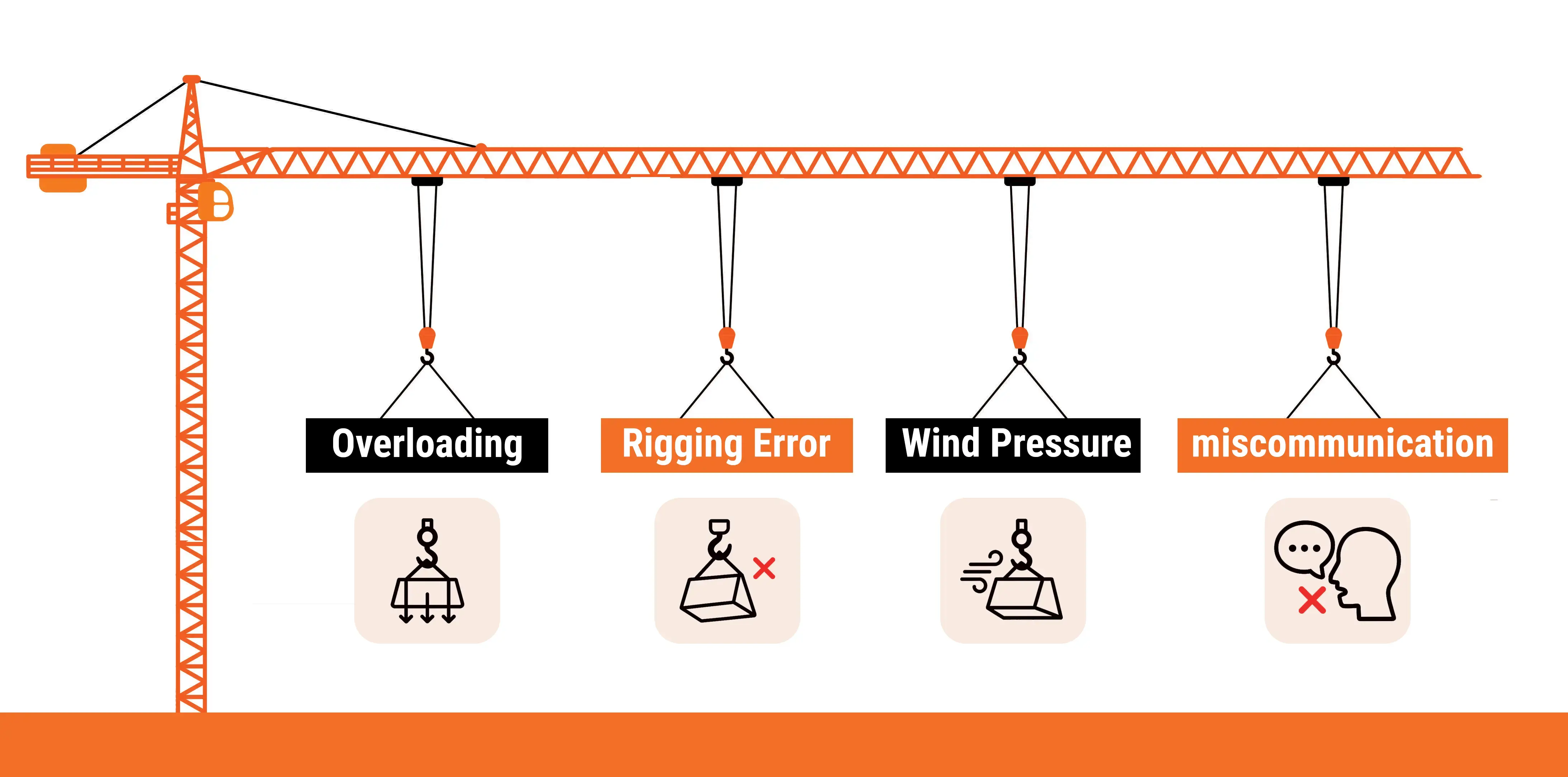

Common Risks in Crane Load Handling

Overloading

Improper Rigging

Wind Pressure and Weather Hazards

Inadequate Communication Between Operator & Ground Crew

Check The Ultimate Guide to Crane Safety & Load Management

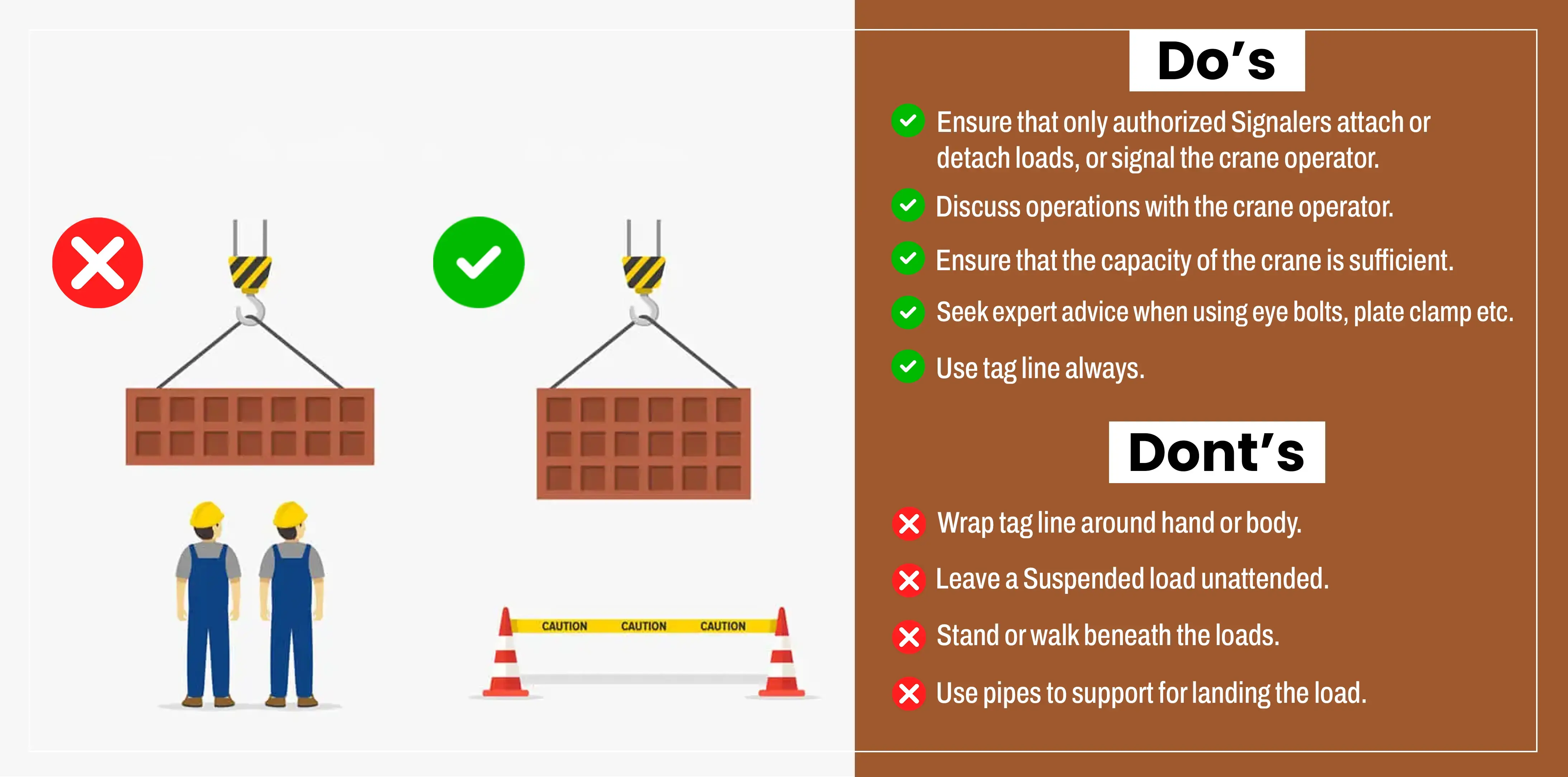

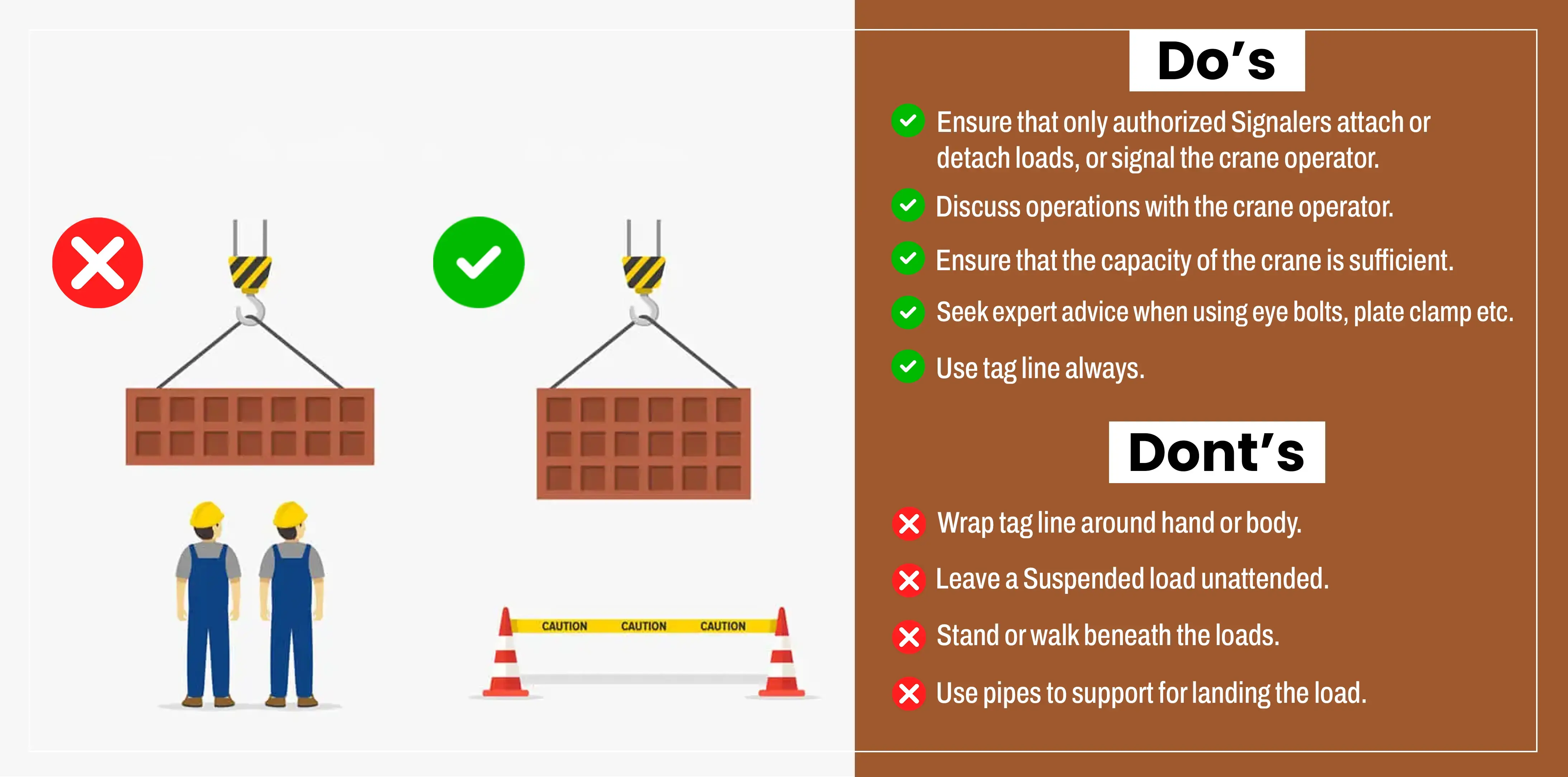

10 Best Practices for Safe Crane Load Management

Here are the 10 essential practices to improve safety:

Pre-Lift Inspection

- Always perform safety checks before operating a lifting equipment.Correct Load Estimation

- Verify the exact weight and center of gravity.Even Material Distribution

- Ensure balanced lifting to prevent tipping.Monitor Wind Speed

- Especially critical for high-rise and tower cranes.Use Trained Operators Only

- Certified professionals lower the risk of mishandling.Employ SLIs and ACDs

- For real-time monitoring and collision prevention.Check Rigging Equipment

- Slings, hooks, and chains must be in top condition.Clear Communication

- Use hand signals or radios between operators and ground crew.Weather Assessment

- Avoid lifts during storms, heavy winds, or lightning.Adhere to Manufacturer Limits

- Never exceed the rated material capacity.

Check What is a safe load indicator and why is it important?

Role of Safe Load Indicators (SLIs) and ACDs

SLIs and Anti-Collision Devices (ACDs) work together to prevent overloading and collisions:

SLI:

Shows live load weight, avoiding overloads.ACD:

Prevents crane-to-crane and crane-to-object collisions with the use of proximity sensors and warning.

View Our Product Specifications

How Anti-Collision Devices Prevent Crane Accidents

Crane collisions on busy construction sites are a real risk. Anti-Collision Devices or ACDs employ proximity sensors and immediate alerts to avoid accidents between cranes, structures, and other infrastructure. Unfold how these devices save your project schedules, machines, and most importantly, your labor force.

Read: How Anti-Collision Devices Prevent Crane Accidents

Applicable Industries

- Real Estate and High-Rise Construction

- Infrastructure (Metro, Bridges, Flyovers)

- Ports and Marine Construction

- Cement, Petrochemical & Steel Plants

Looking to implement these best practices on your next site?

Request a Quote Rental or Purchase Or Speak to our crane safety team today

FAQs

-

1. Why is load management of cranes important?

Accurate load management is what guarantees safety, compliance with regulations, and less wear-and-tear on lifting gears.

-

2. Can I use an SLI on all types of cranes?

Yes, SLIs are compatible with tower, mobile, derrick, and even passenger hoists.

-

3. What's the best device to prevent overloading?

Safe Load Indicators are the best tools to prevent overloading and alert operators in real-time.

-

4. How do ACDs help in heavy duty machine operations?

They reduce the risk of collision, especially when multiple cranes are operating in tight urban zones.

-

5. Are these practices mandatory?

They are part of ISO and CE recommendations and widely followed across India’s leading projects.